GYMDA Manufacturing Lab

Overall Facilities & Capabilities

Our China facility provides moderate-to-high volume manufacturing as well as sourcing capabilities for packaging, materials, extra PPE categories and more.

The Journey of GYMDA Gloves

Quality Control to the Most Details

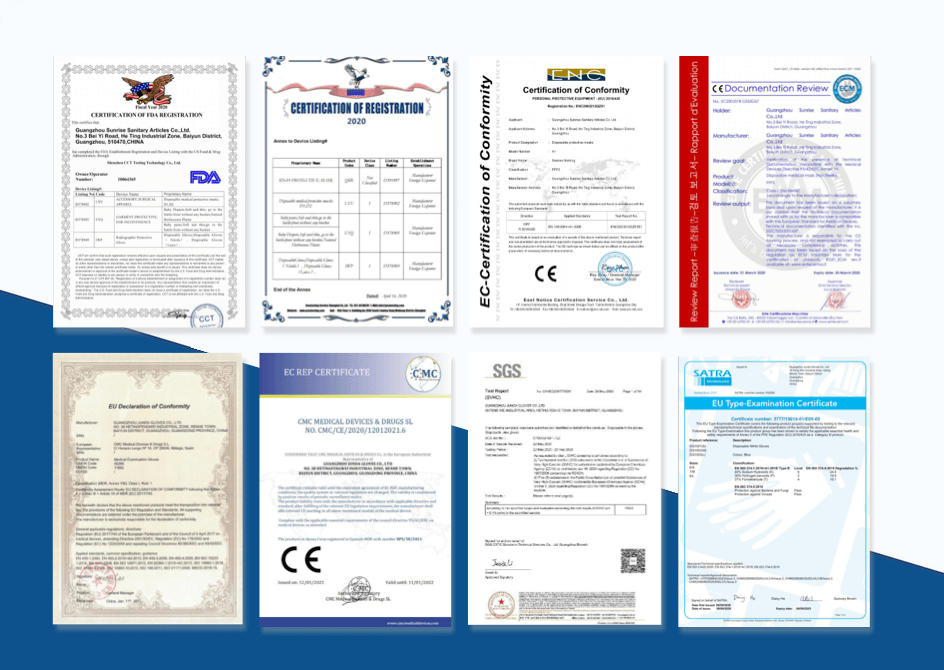

GYMDA is a ISO certified company. Quality control is built into every step of GYMDA’s production process. Starting from selection of raw material till the outgoing finished product, we strictly adhere to customer specifications to ensure that quality is monitored and maintained at every step.

Quality Report before Shipping

After production, the gloves are sent to Testing Lab and then an overall quality check is carried out on a sample batch to ensure they reach the required standard.

Once approved the gloves are then released to the final pre-packing quality checks, at which stage a sample is tested for thickness faults, tensile strength, holes, and weak points. Any gloves that fail are manually re-sorted where only qualified gloves are then handpicked for packing.

Quality to the last minute: GYMDA Quality Report