Like with most products you purchase, doesn’t it feel good to know that someone is looking out for the quality and safety of the gloves you are buying? Indeed, purchasing disposable gloves for protection seems easy, but in reality, it is not. Why? Because there are many variants available in the market, and choosing one can be so overwhelming.

Here are the things you need to contemplate about whenever buying gloves to make sure you only get the best quality out there. Let us start!

Not All Gloves Have the Same Quality

You should know that disposable gloves come in various selections. It ranges from heavy-duty work gloves to medical-grade. The powder-free examination gloves are specially designed for the healthcare sector, where latex and nitrile gloves increase in popularity. They are available from size small through to size large or extra large and easy to put on.

Powdered or powder-free gloves come in various types of components. The most common types of glove material are nitrile rubber, vinyl, and natural latex rubber. These types are based on raw materials with price fluctuations that rely on particular market factors. Altogether, nitrile is usually considered premium to latex, which is in turn considered premium to vinyl. The truth is that materials are not all the same in performance and can be more suited to a user dependent on the environment and application.

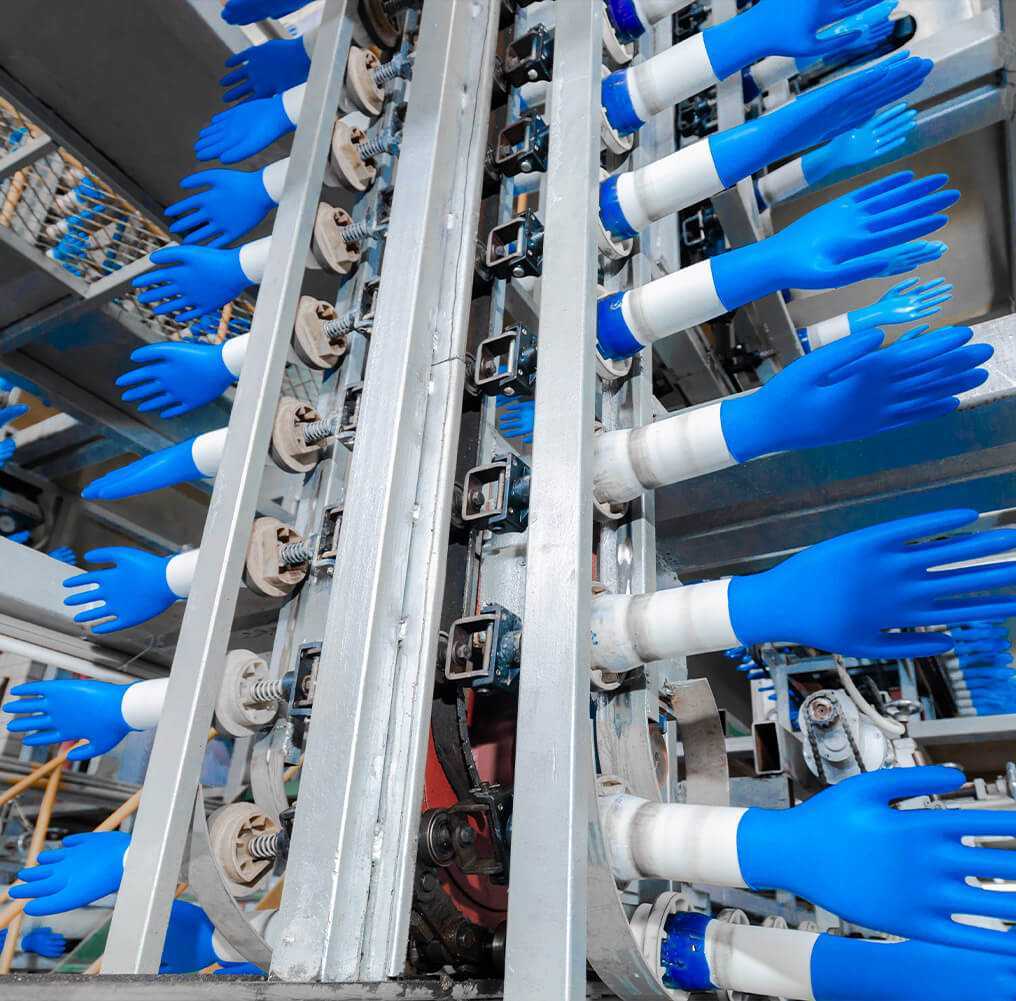

The Product Went Through a Quality Control

You can confirm the best quality of gloves through its maker and their facilities in producing disposable gloves. Verify if your trusted manufacturer or supplier performs a series of tests to guarantee the safety of their consumers. Here are the following tests that should have been performed in quality control for gloves:

- Glove friction testing

- Glove leakage testing

- Glove elongation testing

- Glove thickness testing

- Glove weighing testing

- Glove heat aging degradation test

- Glove pH testing

- Glove dimension testing

Your Supplier has Certifications

Another thing that can give you peace of mind is to know that your reliable glove manufacturer has product certifications. This ensures that each stage of the production process meets the required standard in glove manufacturing. Note that your supplier must be ISO certified, along with other certifications like FDA certification.

Gloves Provide Comfort

Disposable gloves provide a more comfortable fit when in use, compared to utilizing a pair of standard rubber gloves. A higher level of comfort is more evident, especially when worn for long periods of time. So if ever you find a glove that fits your hand nicely and feels convenient on your hands, then that is it. You found your ideal set of gloves.

Low Priced Gloves Don’t Mean You Save More

Among the biggest mistakes in purchasing gloves is choosing one based on their price. Keep in mind that the overall value is much more complicated than just the price of a pair of gloves. Moreover, buyers should consider performance in the application, comfort for the wearer, protection and safety risks, and productivity.

Several disposable gloves are not properly formulated or processed. This is because they are often under-cured and do not last for prolonged application with high levels of failure, particularly for puncture resistance. Did you know that the medical examination consumes the most disposable nitrile gloves globally? Moreover, nurses, the most significant users, commonly wear a pair of gloves for a few minutes only before discarding and replacing them for each new patient.

Contrarily, many industrial applications need 2-4 hours of extended use of a single pair of disposable gloves. This continuous length of time stresses the glove longer. In addition, it can lead to failures in a glove that would not usually happen during a short, routine medical exam. Therefore, choosing a properly formulated glove and processing it to withstand the application for more extended use times is essential.

Can You Measure Glove Quality?

Glove thickness is a crucial measurement and is generally taken from the palm area. In the EU, it is measured in mm, and in the US, mil thickness is used. However, glove thickness only tells us just one part of the story.

The AQL (acceptable quality level) is a globally recognized quality standard designed to evaluate the statistical quality control of products including medical latex-free gloves. Hence, it is used to measure the percent likelihood of defects in a batch of disposable gloves.

An AQL result of 4.0 acknowledges the statistical probability that usually, there are less than 4% of the gloves with defects in every batch produced. The most common AQL numbers in Europe and the UK are both 1.5 and 4.0. Still, you can also get 1.0 and 0.65 AQL-rated gloves. These are often used in specialist industries such as microbiology labs, especially when chemical-resistant gloves are needed.

Conclusion

And that concludes our article. We hope that this section has been helpful. If you are looking for a reliable manufacturer and supplier of PPE gloves, check out our website at http://gymdappe.com/. Gymda Medical is a well-known PPE global manufacturer. We can’t wait to be your business partners. Reach us today!